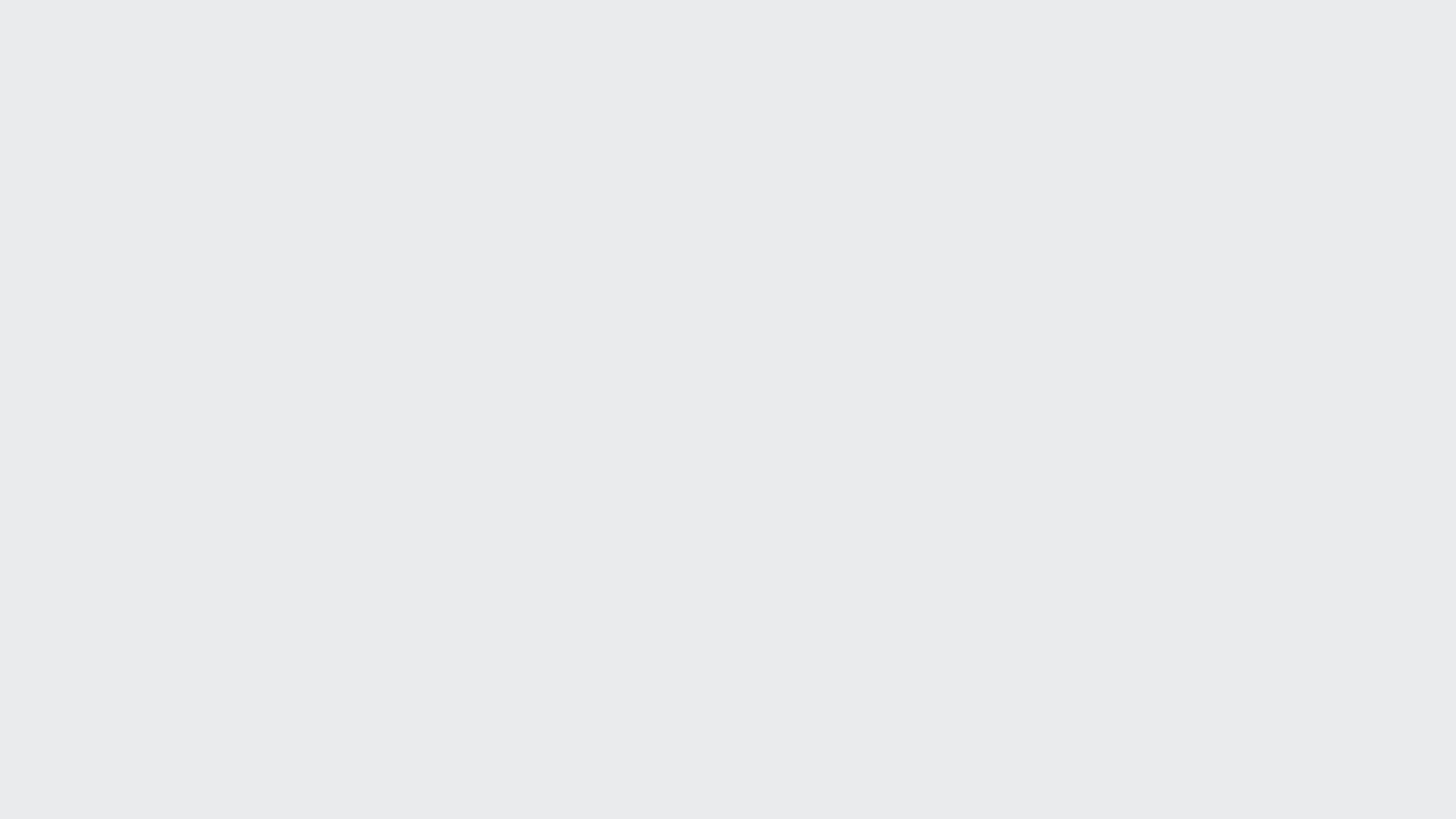

PLM for mechatronics solutions

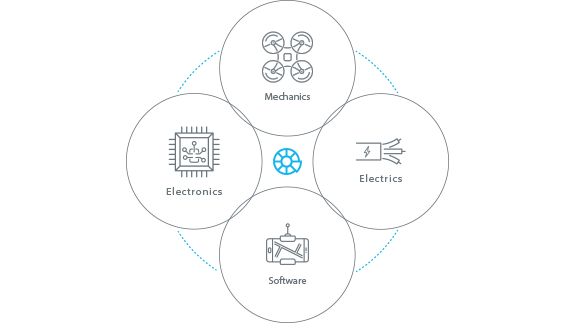

Product Lifecycle Management | PLM becomes ever more demanding because companies increasingly need to integrate electric, electronic, firmware, and software components into their mechanical products – this is called mechatronic product development. Although mechatronics is gaining more and more importance for product development, in many cases the MCAD and ECAD design teams still work within different system landscapes. The result: not transparent design stages with possible conflicts between MCAD and ECAD design departments.

Taking innovations to the market quickly and with reasonable effort

How can we reduce time to market for our mechatronic innovations? How do we meet confirmed delivery dates without problems and how do we comply more easily with cost constraints? Are these questions you are currently facing?

Digital business processes help you achieve these goals. They provide easy access to valid product and project data and can be integrated across all departments. Digital business processes are the basis of correct decisions and flexible end-to-end processes, making it easy to feed change requests into the technical and commercial divisions of the company.

The intelligent direct integration of engineering tools into PLM solutions from SAP is a step forward towards a future-proof innovation environment.

New teamwork in the product development process

The traditional, sequential development processes are outdated today. Complex mechatronic products require parallelized development processes.

With its mechatronic data model, PLM software from SAP creates the basis for high project and data transparency. Team members can access the shared data and processes at any time. This considerably simplifies the collaboration during product development and automatically brings teams closer together.

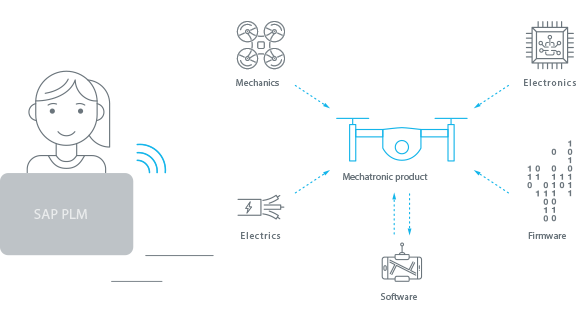

MCAD and ECAD integration in one single platform – just perfect for mechatronic product development

SAP Engineering Control Center | SAP ECTR is an important building block for PLM solutions from SAP. As the strategic integration platform for authoring tools of all kinds, SAP ECTR is the ideal basis for a holistic mechatronics solution. It integrates MCAD and ECAD systems, as well as software into PLM in SAP, and provides direct access to SAP ERP. This way, product data from all development disciplines is available company-wide and can be managed easily and efficiently.

Advantages at a glance

Single Source of Truth increasing data quality and consistency

Cross-domain linking of product and project data

Greater flexibility and shorter reaction times for responding to market changes

Higher process integrity thanks to transparency and clarity

Optimal exchange of information and knowledge based on shared data and processes

Cost saving thanks to fewer IT systems and joint purchasing of components

How design engineers enjoy working with SAP

PLM software from SAP is accessible directly in the familiar CAD environment, a feature that is especially popular in electric and electronic engineering. Smart integrations facilitate the engineers’ daily work through automation of routine tasks.

This includes:

Ideal for development teams

Development teams fully benefit from a holistic mechatronic approach for manifold reasons. On the one hand, PLM software from SAP synchronizes ECAD data with data from MCAD, firmware, and software, and it also synchronizes the workflows. On the other hand, SAP PLM provides a platform for data exchange, e.g. for ECAD / MCAD collision tests. To keep everyone in the loop, SAP ECTR offers an up-to-date overview of all products, structures, and relations in mechatronics. Finally, the integrated viewer displays 2D and 3D data, regardless of the CAD system used.

All of this contributes to faster coordination and validation. And the highlight: PLM software from SAP even takes care of BOMs across all disciplines.

You are looking for a strong partner for your own digital journey?

Contact us today!

You are already a customer and have a question or are faced with a specific challenge?

Visit our Support Area >